Once I had the cables in the Power Box, I needed to figure out how to fuse this whole thing. There's no room for the store-bought fuse case in the box, so I had to make my own custom fuse case.

I used 2 insulating cylinders and pins to create a fuse holder. Then I replaced one of the screws on the + branch with a 30mm pin, tightened the original connection with nuts, and made a connection to my fuse from the top of the pin. I solved the minus with the same 30mm pin.

All that remains for me is to solve the question of where to place the display from the inverter in the car (which I modified so that it can be connected to the inverter with any "LAN" RJ45 cable)

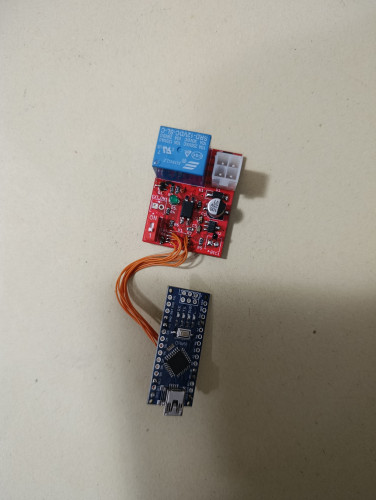

and solve the problem so that the inverter can be started even without the key in the ignition switch, but I already have a solution for that, which includes its own 12V battery charging module that can turn on the contactor in the traction battery. The module will be able to work with both a 12V gel battery and a 12V lead battery (just switch the lead/gel switch on the module), it has a built-in thermometer that changes the conditions for minimum and maximum battery voltages and at the same time an input for external switching on of the inverter even without the ignition switch on and automatic resetting when switching on and off the ignition switch in case I forget to turn it off manually myself

- prototype